Soundproofing & Acoustic Insulation Group

Introduction

KarZah, Advanced Materials, offers this group the technical solutions for soundproofing & acoustic insulation, and echo absorption. Modern life, machinery, equipment, speakers, and our different daily activities have all contributed to increasing sound levels and noise pollution. Consequently, necessities have emerged to reduce those levels to safe limits and to insulate sources when reduction is not achievable. Moreover, we address and resolve echo problems that can be present in different current and new locations. Moreover, our work includes insulation of residential rooms, conference rooms, auditoriums, electrical generators, and other areas in the following sectors:

- Residential sector, including homes, villas, and apartments

- Educational sector, including schools, university rooms, auditoriums, and institutes

- Hospitality sector, including hotels, furnished apartments, and resorts

- The business sector like company head offices, meeting rooms, and training centers

- Industrial facilities and industrial machinery & installations

- Occasion halls

- Hospital rooms and health centers

- Sound and acoustic studios

- Sound recording facilities and recording rooms

Commercial Names

- Sound Insulation

- Acoustic Insulation

- Echo Absorbing

Features of Soundproofing & Acoustic Insulation Group

This group has many features. Below are some of the important ones:

- Improves place environment and convenience

- Improves professional work conditions

- Provides privacy

- Improves safety

- Improves security

It is essential to understand our clients’ needs to be able to propose the most suitable options. Accordingly, we study and analyze the location, the application, and the surrounding factors. Our technical proposals cover the type of materials, specifications of layers, and methods of installation required for the complete job.

For example, music and sound recording studios require an advanced acoustic insulation system and only basic types of echo-absorbing materials. On the contrary, university auditoriums require less complex acoustic insulation systems and more advanced echo-absorbing materials. Therefore, each case demands a detailed evaluation to allow us to come up with a technically sound proposal.

Building Elements that Require Acoustic Insulation & Echo Absorption

Specifications, the type of application, and site conditions determine what work we should perform. We can execute acoustic insulation and echo absorption work on the following building elements:

- Floors

- Walls

- Ceilings

- Doors

- Windows

Materials Used in Acoustic Insulation and Echo Absorption

There are so many materials used in soundproofing, acoustic insulation, and echo-control jobs. Below are the major ones we usually use in our work:

Rock Wool Panels

This material is made from a specific type of basalt rock. It consists of two layers: Rock wool and an aluminum reinforced back sheet that is capable of absorbing sound. Rock wool panels are easy to use and install on floors. In addition to its acoustic insulation properties, rock wool panels are suitable as heat insulation materials. Moreover, panels do not rust, and more importantly, they are environmentally friendly.

Cork Sheet

Cork sheets are made from natural cork extracted from cork oak bark. It undergoes a manufacturing process to form easy-to-use layers. Cork sheets are easy to cut and use on walls, floors, ceilings, and inside doors for sound and heat insulation.

Flexible Sheets and Flexible Rolls

Flexible sheets and flexible rolls are products of natural rubber, synthetic rubber, or petroleum materials. Due to their distinctive properties and high flexibility, they became suitable for sound and heat insulation.

Sawdust

Sawdust is one of the best materials for sound insulation and sound absorption. Thanks to its small particle size and nature, sound waves break, get absorbed, and do pass through. We usually use sawdust in the form of sheets or in its free shape inside the drywall system steel frame.

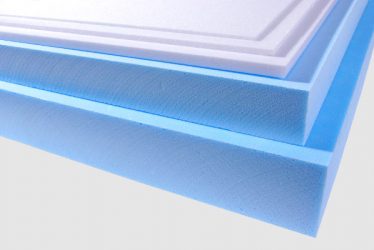

Blue and White Polystyrene Boards

Polystyrene boards are petrochemical products that are excellent thermal insulators and satisfactory for sound insulators. They break and absorb the sound waves inside the bubbles that are present in their structure. Polystyrene boards are light in weight and easy to handle during cutting and installation. Their affordable price makes them very suitable for insulation jobs.

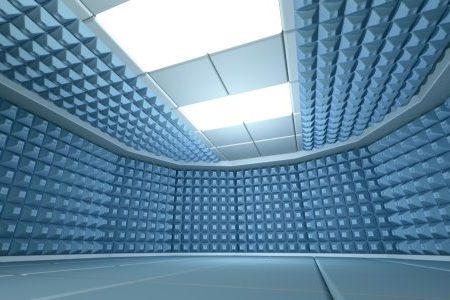

Sponge Foam Panels

Sponge foam panels are soft and flexible material that has a wavy or pointed surface. They break sound waves and prevent them from bouncing back, which results in damping down the echo in place. Their flexible structure reduces the level of sound wave penetration. We usually install them on walls and ceilings.

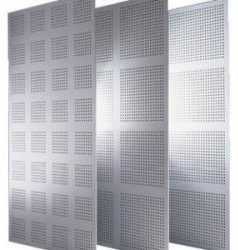

Perforated Gypsum Boards

In addition to their being one of the essential walls and ceiling finishing materials, gypsum boards are good sound insulators. We usually use them in residential and commercial buildings. However, perforated gypsum boards, have even superior sound insulation and echo absorption qualities due to the holes they have. On the other side, they are easy to install and paint, and more importantly, they are not costly.

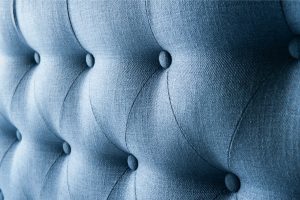

Leather Upholstery and Fabric Upholstery

This process is more beneficial for sound absorption than for sound insulation. We often use leather or fabric upholstery in cinemas and in sound recording studios.

Sound Insulation of Electric Generators and Machines

Due to the increasing safety measures, it became critical to reduce and control noise levels emitted from machines and generators. Therefore, there are typically many methods to achieve the required results:

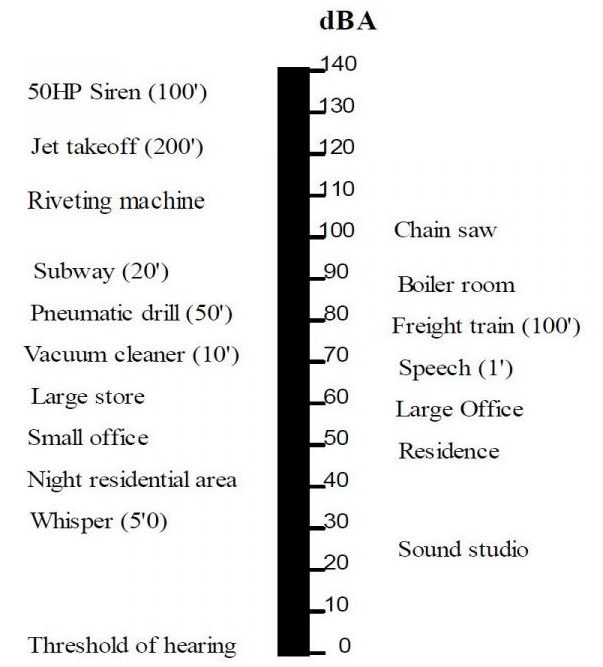

Distance

Increasing the distance is one of the simplest ways to reduce noise levels. In this option, we increase the space between the source of the sound and the place we want to isolate. The larger the distance, the less the noise level. The general rule is, that doubling the distance reduces the noise level by 6 dB, but this applies to open spaces.

Solid Barriers

Solid surfaces work as barriers that reduce noise transmission by reversing sound waves. Properly insulated covers can reduce by at least 10 dB.

Acoustic Insulation Covers and Insulation Cages

Insulated covers and cages can absorb sound waves produced by machines resulting in damping noise levels. However, it is crucial to evaluate the mechanical, electrical, and cooling effects on the machine before choosing this option.

AVM (Anti-vibration Mounts)

Placing anti-vibration mounts or vibration stabilizers under machines and electric generators isolates vibrations and reduce noise transmission. There are many different options, such as (rubber pads, spring mounts, and dampers). The choice of the correct option depends on the machine and the level of noise reduction we want to achieve.

Fabrication of Sound Insulation Cage for Machines and Electric Generators

The Steel Frame

We use steel angles to fabricate the outer frame on which we will fix the insulation materials.

The Insulation Materials

We use three types of soundproofing materials (sponge, egg tray carton, rubber)

Cooling Fan

We install an extraction fan on the top of the cage for the purpose of cooling the machine. The fan extracts the hot air from the top, while fresh colder air enters through side holes in the cage.

Insulation of Windows and Doors

When thinking about isolating the sounds passing through doors, we should really think about the types of doors to install. We should either choose doors with pressed wood, or select soundproofed doors stuffed with cork, polystyrene, or rock wool. As for the windows, the approach is a little bit different. On the other side, in windows, we need to seal all spaces and openings around the frame. Moreover, using a thick glass pane has a substantial positive effect on the reduction of sound transmission; however, it is best to use double-glazing.

When KarZah created this group, it was necessary to get acquainted with the professional information related to the work. We provide our team with the necessary scientific background as well as the needed training to perform the job satisfactorily. In addition, we maintain a close follow-up to what is new in this field.

Installation Methods of Acoustic Insulation Materials

We generally install acoustic insulation materials and echo absorption materials on the following building elements:

Walls

We install the insulation materials on the wall in the following ways:

- Directly on the wall using glue, nails or screws then cover the insulation materials with the drywall system boards

- Inside the steel structure of the drywall system

- In between wooden studs

Ceilings

We install the insulation materials on the ceilings in the following ways:

- Directly on the wall using glue, nails or screws then cover the insulation materials with the drywall system boards

- In between wooden studs

Floors

- First, we install a layer of black flexible insulation material. Then we install our intended insulation material. Then we lay a layer of wooden boards, and last, we introduce a final solid layer of flooring. The final solid layer of flooring can be a cement layer, wood parquet, or tiles.

Locations that Require Acoustic Insulation and Echo Absorption

Some of the areas that benefit from our acoustic insulation and echo absorption solutions are:

- Sound recording studios

- Cinemas and theaters

- Lecture rooms and auditoriums

- Meeting rooms

- Residential rooms

- Rooms in hospitals

- Rooms in hotels

- Ballrooms and banquet hall

- Generators and generator rooms

Scientific Information

- dB (Decibel) is a unit used that measures the intensity of sounds. It is one-tenth of a bel

- NCR (Noise Reduction Coefficient) is an average rating of how much sound a specific material could absorb. In other words, it reflects how much sound intensity could a given material reduce