Raised Floor/Raised Flooring Group

Introduction

KarZah, Advanced Materials, introduces the Raised Floor/Raised Floor group in response to several business sector requirements. Commercial, industrial, medical, hospitality, and other areas can utilize this flooring to serve their various functional needs.

Applications of Raised Floor

We use the raised floor to make electrical or mechanical floor installations. Moreover, the raised floor provides fast and easy access for maintenance and repair work. On the other hand, other technical domains could also utilize this type of floor. For example, these floors are widely present in information technology, data centers, computer and server rooms, and control rooms. Therefore, we believe these floors can serve the following purposes: Now Test.

Raised Floor for Mechanical and Electrical Networks

We use this type to pass pipes or cables underneath the floor. It is generally available in areas that have much electrical and electronic equipment. Eventually, we can maintain the internal space and, at the same time, protect the pipes and cables from damage.

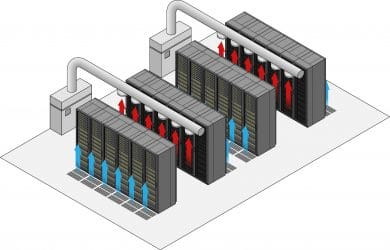

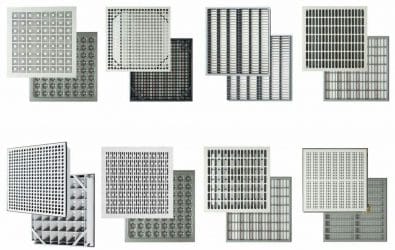

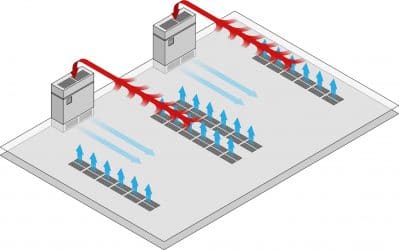

Raised Floor for Ventilation Purposes

We use this panel to ventilate tools and equipment through a cold-aisle containment system (CAC). This system distributes cold air inside the room from the floor to the ceiling.

Ventilation occurs through panel perforations with a ventilation ratio between 15-55%, depending on the hole diameter and airflow. However, designers have to take into consideration the following aspects:

- Building ceiling height as this flooring decreases the overall height.

- Sound insulation for this type of flooring is based on the thickness of the panel surface.

- We are completely sealing off the electrical/mechanical extensions hidden underneath the panels while permitting access to the hidden area. We seal off the extensions to keep out rodents and insects.

Raised Floor for Storage Purposes

This type is one of the best ways to utilize space. We design a top hatch relative to the occupant’s height so that it is easy to open and close.

Raised Floor for Drainage Purposes

This flooring type handles the possibility of having an increased water level due to weather factors like rain. In addition, the flooring protects the hidden internal elements from possible damage.

Raised Floor Systems, Accessories, and Tools

The raised floor system consists of 4 four main components:

Pedestals

This component comes in galvanized iron. It contains an adjustable stem that lies on the original building floor. The raised floor has different heights:

- 300 – 350 mm

- 600 – 650 mm

- 1000 – 1050 mm

Customers can have higher or lower elevations with a special request. The raised floor platform can be additionally reinforced and given optional lighting if necessary.

Stringers

Stringers are GI horizontal cross-members that are 540 mm long. They lie down on the top of pedestals and connect them. Stringers form a bearing grid on which panels lie down.

PVC Base, Gaskets, and Screws

PVC bases are bases that have four divisions. Each division holds a corner of the raised floor tile, securing it in place and preventing it from moving. The primary purpose of screws and gaskets is to fasten stringers to pedestals before placing the tiles on them.

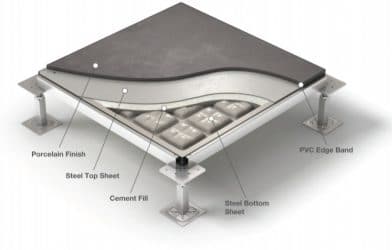

Panels (Tiles)

Panels or tiles are the components that we place on the top of the raised floor platform. They are manufactured to exact dimensions and put together to constitute the room’s new floor. Experts categorize panels in different ways, for instance:

Panel Internal Composition

- High-density wood chips

- Chemicals (calcium carbonate, calcium sulfate, calcium silicate, light cement mixtures)

Panel Bottom Materials

- GI (Galvanized Iron) metallic sheet

- A metallic sheet with an Aluminum coat

- Aluminum foil

Panel Thickness and Dimensions

Raised Floor Panels come in several thicknesses (like 30 mm, 40 mm, and others too). Moreover, they come in different dimensions:

- 600×600 mm

- 600×400 mm

- Other dimensions (special request)

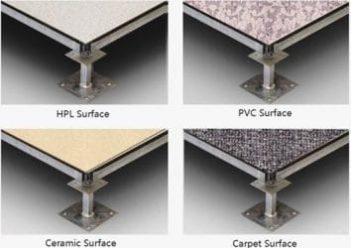

Panel Top

Panel tops come in different types:

- No upper layer (galvanized metallic sheet or Aluminum coated metallic foil).

- Vinyl planks (homogeneous, heterogeneous, and other vinyl types) at different thicknesses (2, 2.5, or 3 mm).

- High-pressure laminate HPL are high-pressured melamine boards ranging in thickness between (0.8/1.2/1.5/1.6 mm).

- Granite board-ceramic ranging in thickness between 8/10 mm.

- Wooden or parquet planks.

- Carpet tile with a thickness between (2/2.5/3 mm).

- Lumen glass panes.

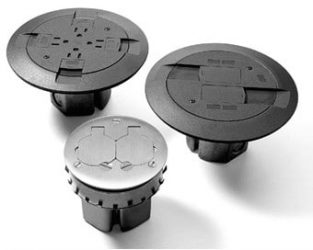

Raised Floor Accessories

The Raised Floor system has several accessories designed to suit the type of application the floor is intended for. Electrical and mechanical purposes are among the top categories these accessories serve.

Installation of Raised Floor

Installation Tools

Below are the tools we need for the installation process:

- Drill

- Level

- Plastic plugs and fasteners

- Hacksaw

Method of Installation

For installation, we follow the following steps:

- First, we prepare the tools needed for installation.

- We place the pedestals on the floor in sets of fours or fives for each panel corner and centre. Five supports are much better as they can handle more weight.

- We determine a starting point at either the room’s corner or the center.

- We install each pedestal and connect it to a stringer using a level to make sure the floor is level.

- After ensuring the floor is level, we attach the pedestals and secure them using plastic plugs and screws. The same applies to the stringers.

- We install the panels, which have a 60×60 cm dimension.

Raised Floor Design Height

We determine the height based on the size of the cables/pipes that we need to hide under the panels. If there are many, the height should be higher to accommodate them. As for storage, the raised floor is relatively higher to increase storage space. However, we should consider the ceiling height in this process.

Raised Floor Features

The raised floor possesses many features. The following are some of the important ones:

- Flexible design

- Installs/removes easily and quickly

- Can be transferred from one place to another and re-used

- Adjustable height and slant

- Humidity resistant

- Fire and Flame retardant

- Electrostatic discharge ESD resistance.

Features of Panels According to Core Material

Features of panels differ according to core materials as follows:

Plywood

- Economical

- Fire resistant

- Supports heavy moving loads

Aluminum

- Lightweight as its density is only one-third the density of steel

- It does not contain any metallic substances

- Excellent for raised access flooring since it has a high loading capacity

Cement Mixtures

- Excellent fire retardant

- Great weight-loading capacity

- Suitable for electrical/electronic insulation

- Non-flammable.

Steel

- Fire resistant

- Lightweight

- Non-flammable

- Epoxy-coated, which has good surface insulation